Gearbox / Transmission

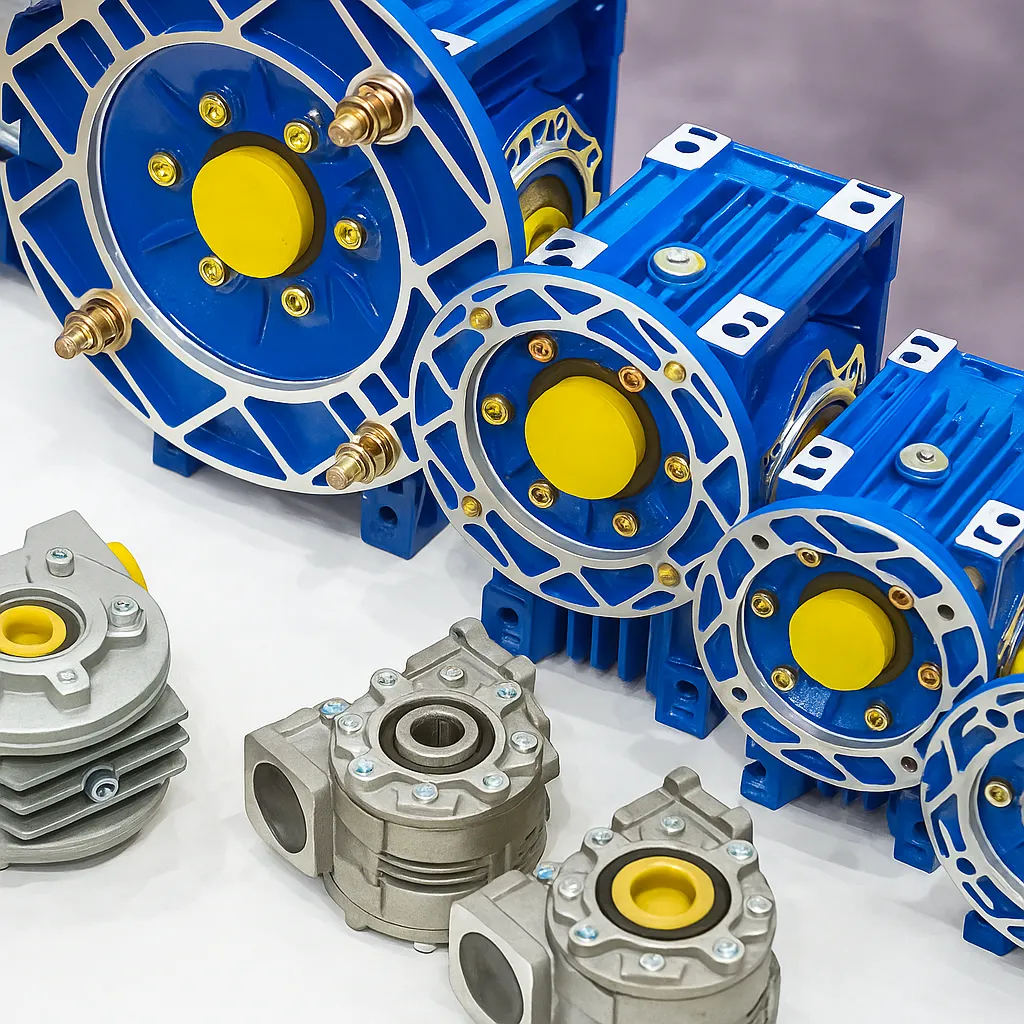

Worm Gearbox

Worm gearboxes are a reliable and efficient solution for transmitting power at right angles while achieving high torque reduction. They use a worm (a screw-like gear) that meshes with a worm wheel, allowing smooth and quiet operation. Because of their compact design, worm gearboxes are ideal for applications where space is limited but high torque is required.

Key advantages include:

High Reduction Ratios – A single stage can provide significant speed reduction.

Compact & Space-Saving – Designed for tight installations without sacrificing performance.

Self-Locking Capability – In many cases, worm gearboxes can prevent back-driving, adding safety to lifting and positioning applications.

Durability & Low Noise – The sliding contact between the worm and wheel ensures smooth, quiet, and long-lasting performance.

Worm gearboxes are widely used in conveyors, material handling systems, packaging equipment, and lifting machinery. Whether you need precise speed control or reliable torque transmission, they offer a cost-effective and robust solution for industrial and mechanical applications.

Helical Inline Gearbox

Helical inline gearboxes are one of the most versatile and widely used types of gear reducers in industrial applications. They feature helical gears mounted on parallel shafts, designed to deliver smooth, efficient, and quiet power transmission. The angled teeth of the gears engage gradually, reducing vibration and noise while improving load capacity compared to straight-cut gears.

Key Advantages:

High Efficiency – Helical gear design minimizes energy loss, often achieving efficiencies above 95%.

Smooth & Quiet Operation – Gradual tooth engagement reduces noise and vibration.

Compact & Versatile – Inline design saves space while handling high torque.

Durable & Reliable – Built to handle continuous duty and heavy loads with minimal wear.

Flexible Mounting Options – Available in foot-mounted, flange-mounted, and shaft-mounted versions.

Helical inline gearboxes are commonly found in conveyors, mixers, crushers, packaging machines, and material handling systems. Their efficiency and reliability make them a cost-effective choice for industries such as manufacturing, food processing, agriculture, and mining.

Whether you need precise speed reduction, long service life, or energy efficiency, a helical inline gearbox offers a proven solution for demanding mechanical applications.

Bevel Gearbox

Our Helical Bevel Gearbox is engineered for precision, durability, and efficiency across a wide range of industrial applications. Designed with advanced bevel-helical gearing technology, it delivers high torque output, smooth transmission, and exceptional energy efficiency in a compact design.

Key Features:

High Efficiency: Up to 96% efficiency, ensuring reduced energy loss and maximum performance.

Compact & Robust Design: Space-saving construction with a high-strength housing for long service life.

Versatile Mounting Options: Available with foot, flange, or shaft-mounted configurations to suit different installation needs.

High Torque Capacity: Ideal for heavy-duty applications with consistent power transmission.

Quiet & Smooth Operation: Optimized gear design reduces vibration and noise levels.

Maintenance-Friendly: Easy access design minimizes downtime and lowers service costs.

Applications:

Conveyors & Material Handling, Packaging Machinery, Mixers & Agitators, Crushers & Heavy Machinery &

Lifting Equipment.

Planetary Gearbox

Our Planetary Gearbox is engineered for precision, high torque, and compact performance in demanding industrial applications. Featuring advanced planetary gear technology, it delivers efficient power transmission, smooth operation, and long-lasting reliability in a space-saving design.

Key Features:

High Torque & Load Capacity: Designed to handle heavy loads and maintain consistent performance.

Compact & Durable Design: Space-saving construction with reinforced housing for extended service life.

Efficient Power Transmission: Optimized gear design reduces energy loss and improves operational efficiency.

Smooth & Quiet Operation: Precision engineering minimizes vibration and noise for safer, more reliable machinery.

Versatile Mounting Options: Available in shaft, flange, or custom configurations to meet diverse installation needs.

Maintenance-Friendly: Easy access for servicing reduces downtime and overall maintenance costs.

Applications:

Robotics & Automation, Conveyor Systems, Packaging Machinery, Mixers & Agitators, Material Handling Equipment, Lifting & Hoisting Systems, Industrial Machinery.

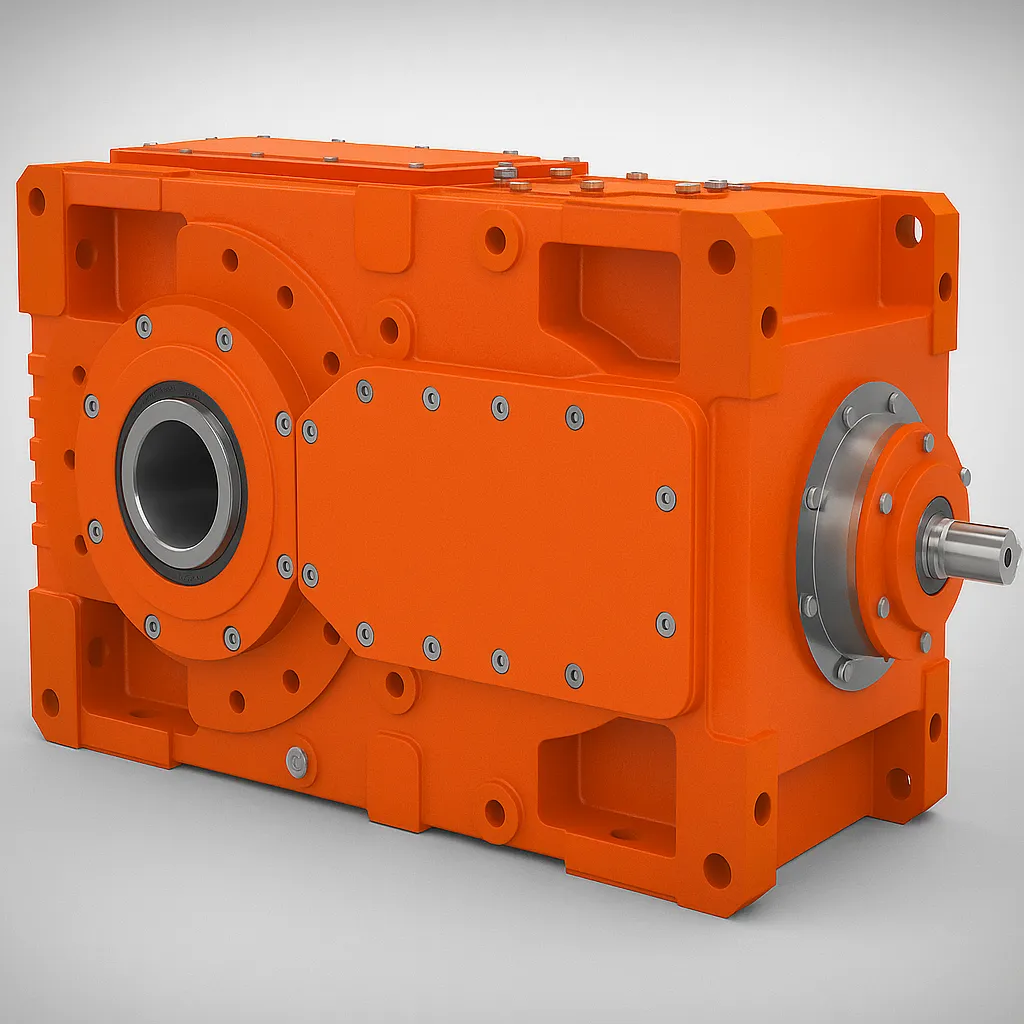

Heavy Duty Gearbox

Our Heavy Duty Gearbox is designed for maximum performance, durability, and efficiency in the most demanding industrial environments. Engineered with high-strength materials and precision gearing, it delivers reliable power transmission, high torque capacity, and long-lasting service life even under extreme loads.

Key Features:

Exceptional Torque Capacity: Handles heavy loads and high shock conditions without compromising performance.

Durable & Robust Design: Built with premium materials and reinforced housing for superior strength and longevity.

High Efficiency: Optimized gear geometry ensures smooth operation and minimal energy loss.

Quiet & Vibration-Free Operation: Precision engineering reduces noise and vibration for safer, smoother machinery operation.

Versatile Mounting Options: Foot-mounted, flange-mounted, or shaft-mounted configurations to meet diverse industrial installation needs.

Low Maintenance: Engineered for easy access and reduced downtime, lowering overall maintenance costs.

Applications:

Mining Equipment, Crushers & Conveyors, Heavy Machinery, Material Handling Systems, Mixers & Agitators, Lifting & Hoisting Equipment, Cement & Steel Plants.

We’re dedicated to serve our customers with the best experience possible. Contact us for all your flued and motion control needs and experience the difference.

Copyrights 2023 | Interpro Africa™ | Terms & Conditions - Created by WEBTHIRTY3

Facebook

LinkedIn

WhatsApp